Collaboration is key to delivering projects efficiently and effectively in architecture, engineering, and construction (AEC). However, traditional workflows often face challenges like inconsistent communication, outdated documentation, and misaligned project data. This is where scan-to-BIM services emerge as a transformative solution.

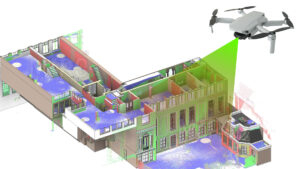

By converting physical structures into precise digital models, Laser scanning enhances collaboration across all stages of construction and design. Let’s explore how this modern technology is reshaping AEC industries and why it’s becoming essential for modern workflows.

Key Features of Scan-to-BIM Services

- Laser Scanning: Captures highly accurate, millimeter-level measurements.

- Point Cloud Data Conversion: Converts raw scan data into detailed 3D models.

- Integration with BIM Software: Works with platforms like Autodesk Revit, ArchiCAD, and others for effective planning and visualization.

- Clash Detection: Identifies and resolves potential conflicts between systems.

- Real-Time Updates: Enables iterative improvements and monitoring during project execution.

Challenges in Traditional AEC Collaboration

In the AEC industries, successful project delivery requires seamless collaboration among multiple stakeholders, including architects, engineers, contractors, and clients. However, traditional workflows often fall short due to outdated tools, fragmented communication, and inefficient processes. These challenges hinder productivity, increase project risks, and escalate costs.

Below, we explore the key challenges that traditional AEC collaboration methods face in greater detail:

Lack of Real-Time Data Sharing

In traditional AEC workflows, data is often shared through static documents like paper blueprints, PDFs, or CAD files. These formats cannot update dynamically, leading to outdated information being used by different teams. The absence of real-time updates creates a lag in decision-making and increases the chances of costly errors.

Inefficient Coordination Between Disciplines

Architecture, engineering, and construction are highly interconnected disciplines, yet traditional workflows often operate in silos. Architects may design without fully understanding structural constraints, engineers might overlook site-specific challenges, and contractors may face differences during execution. This lack of integration disrupts workflows and delays project timelines.

Limited Visibility Across Project Phases

Without a centralized platform, stakeholders often lack visibility into the entire project lifecycle. This makes it difficult to track progress, monitor budgets, or anticipate issues. As a result, project managers may only identify problems after they’ve escalated, leaving little room for proactive solutions.

Clash Detection Challenges

In traditional workflows, detecting and resolving clashes between systems (e.g., plumbing interfering with HVAC ducts) is often reactive rather than proactive. By the time clashes are identified, they typically require significant rework, impacting budgets and timelines.

Difficulty in Handling Complex Projects

As construction projects grow in complexity, traditional methods struggle to accommodate the volume of data and coordination required. Large-scale projects like airports, hospitals, or mixed-use developments involve multiple stakeholders, phases, and interdependent systems, which cannot be effectively managed using outdated tools.

Delays in Renovation and Retrofitting Projects

Renovation projects often require accurate documentation of existing structures. Traditional surveying methods are time-consuming and prone to errors, leading to delays in design and execution. Moreover, missing or outdated building documentation can result in unforeseen challenges during construction.

Increased Environmental Impact

Inefficiencies in traditional workflows—such as rework, material wastage, and inaccurate procurement—can lead to higher carbon footprints. These impacts are becoming increasingly important to address as sustainability takes center stage in the construction industry.

Data Silos

In traditional workflows, teams often rely on separate tools and software systems that lack compatibility, leading to data silos. Information is stored in isolated formats, making it difficult to share and align across disciplines. This lack of integration often results in outdated data, manual transfer errors, and wasted time reconciling disparate information instead of focusing on core tasks.

Inaccurate Measurements

Accurate measurements are essential for any construction or design project. However, traditional methods like manual surveying or relying on outdated 2D drawings often lead to errors. These inaccuracies can cause design mismatches, disrupt workflows, and result in costly delays or rework during construction.

Communication Gaps

Effective communication is critical for aligning project teams and ensuring smooth execution. Traditional AEC workflows often rely on outdated methods like email, paper-based documentation, or standalone tools that fail to foster collaboration. These gaps lead to delays, misunderstandings, and outdated information, resulting in inefficiencies, duplication of effort, and lost time.

Cost Overruns

Inefficiencies in traditional AEC collaboration often lead to increased project costs. These arise from errors requiring rework, lack of coordination between design and construction teams, delays caused by communication gaps, and unforeseen challenges due to outdated or inaccurate information. For example, a poorly communicated design change might result in wasted materials or construction errors, inflating overall expenses and timelines.

These challenges can delay projects, increase costs, and impact quality. Scan-to-BIM services address these problems by providing a single source of truth for all project stakeholders.

Benefits of Scan-to-BIM Services for Collaboration

Laser scanning services have transformed collaboration in the AEC industries by capturing accurate data from physical structures and converting it into digital BIM. This allows stakeholders such as architects, engineers, contractors, and facility managers to work with updated information, improving communication, coordination, and decision-making while reducing errors for more successful project outcomes.

Centralized Data Hub

Scanning creates a unified digital platform where all teams can access the same data. This eliminates miscommunication and ensures everyone works toward the same goals. Whether it’s architects drafting designs or contractors executing construction, the BIM model serves as a common reference point.

Enhanced Accuracy and Precision

With laser scanning, it delivers highly accurate digital models. This precision reduces the risk of costly errors and ensures better alignment between design intent and execution.

Improved Clash Detection

Integrating scanning with clash detection tools allows teams to identify conflicts between structural, mechanical, electrical, and plumbing systems early in the design phase. This preemptive approach minimizes delays and ensures smooth execution.

Better Communication Across Disciplines

Laser scanning technology bridges the communication gap between architects, engineers, and contractors. Teams can collaborate more effectively using shared models, reducing delays caused by misunderstandings or incomplete information.

Simplified Renovation and Retrofitting

Renovation projects often require working with incomplete or outdated building documentation. It provides an accurate representation of existing conditions, enabling teams to plan upgrades or retrofits more efficiently.

Real-Time Updates and Monitoring

BIM models can be continuously updated throughout the project’s lifecycle, providing stakeholders with real-time data. This ensures better decision-making and strengthens accountability across the project.

Applications of Scanning in AEC Industries

Scan-to-BIM technology is transforming the AEC industries by providing accurate digital models of physical structures. These models enhance collaboration, improve precision, and streamline processes across a variety of applications. Below are key areas where Scan-to-BIM is making a significant impact:

Historic Preservation

Preserving historic buildings requires precision and attention to detail. It captures intricate architectural elements and creates digital replicas, ensuring preservation efforts are accurate and respectful of the original design.

Large-Scale Infrastructure Projects

In complex projects like airports, bridges, and railways, It enables seamless collaboration among multidisciplinary teams. It ensures coordination across phases, from planning to construction.

Facility Management

Even after construction is complete, BIM models can be used for facility management. These models provide detailed information about building systems, helping with maintenance and future upgrades.

Why Scan-to-BIM Services Are a Game-Changer?

Cost Savings

By reducing errors and preventing rework, Scan-to-BIM services save time and money throughout a project’s lifecycle.

Improved Decision-Making

The detailed insights provided by BIM models enable stakeholders to make informed decisions, reducing uncertainty and improving outcomes.

Sustainability

Accurate digital models support sustainable design practices by optimizing material use and reducing waste.

Conclusion

Scan to BIM services are revolutionizing the way AEC industries collaborate, offering unmatched precision, efficiency, and integration. By creating a single source of truth through detailed digital models, this technology reduces errors, improves communication, and ensures project success.

Whether you’re planning a new construction, renovation, or facility upgrade, investing in our Scan-to-BIM services can elevate your project outcomes.

Recent Comments