Point Cloud to Building Information Modeling (BIM) is increasingly being utilized in designing, constructing, and maintaining water treatment facilities and pumping stations. This technology offers several benefits, including improved accuracy, enhanced collaboration, and streamlined workflows.

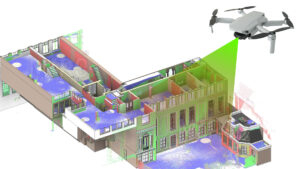

Point Cloud to BIM technology plays a crucial role in designing, maintaining, and renovating water treatment facilities and pumping stations. By capturing accurate 3D representations of existing structures through laser scanning, Point Cloud to BIM allows engineers and facility managers to create detailed Building Information Models (BIM) that reflect the real-world conditions of these critical infrastructures. This level of precision is essential for identifying potential issues such as equipment clashes, pipe misalignments, or space constraints. It also supports future upgrades and maintenance by providing accurate as-built models, minimizing downtime and costly errors during construction or retrofitting projects.

Point Cloud to BIM services ensures that every component is adequately coordinated in water treatment facilities and pumping stations, where complex mechanical, electrical, and plumbing (MEP) systems are involved. The 3D models created from point cloud data facilitate better decision-making by allowing engineers to visualize the layout and operational workflows. This technology helps optimize space usage, improve system efficiency, and ensure compliance with safety standards, ultimately enhancing the facility’s performance and extending its operational lifespan.

How is Point Cloud to BIM applied explicitly in these critical infrastructures?

As-Built Modeling

Point Cloud to BIM enables the creation of precise as-built models for existing water treatment facilities and pumping stations. By scanning these facilities using laser technology, engineers can capture existing structures’ exact dimensions and layout. This information is crucial for planning upgrades, renovations, or expansions while ensuring compatibility with the existing systems.

Design and Planning

BIM models generated from point cloud data allow detailed visualization of water treatment facilities and pumping stations. Engineers can create 3D models reflecting intricate pipes, valves, and equipment layouts. This enhanced visualization aids in better design decision-making and facilitates compliance with regulatory standards.

Clash Detection and Coordination

Point Cloud to BIM Services significantly improves the ability to detect clashes and coordinate various systems before construction begins, such as mechanical, electrical, and plumbing (MEP) systems. By analyzing the BIM model, project teams can identify potential conflicts and resolve them early in the design process, reducing the risk of costly rework and delays during construction.

Facility Management and Maintenance

Once a water treatment facility or pumping station is operational, Point Cloud to BIM models can serve as valuable resources for facility management. These models provide accurate information about the layout and components of the facility, making it easier to plan maintenance tasks, monitor asset performance, and implement upgrades.

Capacity Analysis and Upgrades

As demand for water treatment increases, facilities may need to expand their capacity. Point Cloud to BIM allows engineers to assess the existing infrastructure accurately and plan for necessary upgrades. By visualizing how new equipment or systems will fit into the existing layout, teams can minimize disruption during installation.

Regulatory Compliance and Reporting

Water treatment facilities are subject to strict regulations and standards. BIM models derived from point cloud data can help demonstrate compliance by providing detailed documentation of facility layouts and systems. This documentation can be invaluable during audits or inspections, showcasing that the facility meets all regulatory requirements.

Emergency Response Planning

Accurate and up-to-date water treatment facility and pumping station models can significantly enhance response efforts in an emergency. Point Cloud to BIM provides first responders with essential information about the facility’s layout, enabling them to navigate more effectively and address emergencies promptly.

BIM Applications in Water Treatment Facilities

- As-Built Documentation: Point Cloud data provides precise as-built documentation necessary for ongoing maintenance and operational planning. This documentation is invaluable for facility managers who need to understand existing systems for upgrades or repairs.

- Renovation and Retrofitting Projects: Point Cloud to BIM integration provides accurate representations of current conditions for existing water treatment facilities undergoing renovations or upgrades. This capability allows engineers to plan modifications effectively without extensive manual measurements or guesswork.

- Facility Management: The detailed models created from Point Cloud data can be used for facility management, helping operators monitor system performance and plan maintenance activities efficiently. Integrating real-time data into the BIM model can further enhance operational efficiency.

- Training and Safety: The visualizations created through BIM can serve as training tools for staff operating water treatment facilities and pumping stations. Safety risks can be minimised by familiarizing employees with the layout and systems before they step on-site.

Challenges of Integrating Point Cloud Data into BIM for water treatment Facilities

Integrating Point Cloud data into BIM for pumping stations presents several specific challenges that can impact project efficiency, accuracy, and overall success. Here’s an in-depth look at these challenges

Data Size and Complexity

Point Cloud data sets are often vast and complex, especially in large pumping stations with intricate systems. The sheer volume of data generated can lead to storage, processing, and management difficulties. This requires advanced computational resources and specialized software to effectively handle large-scale Point Cloud projects.

Accuracy and Registration Errors

Achieving precise alignment of multiple Point Cloud scans is a significant challenge. Registration errors can occur when combining data from different scans, leading to inaccuracies in the resulting BIM models. This misalignment can result in discrepancies that affect design elements and operational efficiency, necessitating rigorous quality control measures to mitigate these errors.

Skill and Training Requirements

Working with Point Cloud data and BIM software requires specialized skills that may not be readily available within all organizations. The need for training personnel to effectively utilise both technologies can pose a barrier to adoption, impacting project timelines and costs.

Compatibility and Interoperability

Ensuring compatibility between different software platforms is crucial for seamless data exchange throughout the project lifecycle. Many BIM tools are primarily designed for new construction rather than existing structures, making integrating Point Cloud data into existing workflows challenging without encountering compatibility issues.

Data Quality and Completeness

The quality of Point Cloud data can vary significantly due to factors such as scanning resolution, occlusions, or environmental conditions during data capture. Inadequate or fragmented data can lead to low-quality BIM models that lack critical details, affecting design accuracy and decision-making.

Time-Consuming Conversion Process

The transformation from Point Cloud data to a usable BIM model is often labor-intensive and time-consuming. This process involves converting geometric information and creating the necessary metadata for practical BIM functionality. The high level of detail captured in Point Cloud may require significant manual modelling efforts, adding to project timelines and costs.

Clash Detection Challenges

While Point Cloud to BIM integration enhances clash detection capabilities, identifying conflicts between existing structures and proposed designs can still be complex. In pumping stations where multiple systems (mechanical, electrical, and plumbing) converge, ensuring all elements fit together without issues requires meticulous planning and execution.

Conclusion

Point Cloud to BIM transforms how water treatment facilities and pumping stations are designed, constructed, and managed. By leveraging the accuracy and efficiency of this technology, industry professionals can ensure these critical infrastructures are built to meet current demands while remaining adaptable for future challenges. As the technology continues to evolve, its applications in the water treatment sector will undoubtedly expand, leading to improved outcomes and sustainability in water management.

FAQs

How is Point Cloud data collected for water treatment facilities?

Point Cloud data is typically collected using advanced laser scanning or photogrammetry techniques, which capture the physical attributes of the facility with high precision.

What are the benefits of using Point Cloud data in pumping stations?

Point Cloud data enhances accuracy, improves project planning, facilitates clash detection, and streamlines stakeholder collaboration throughout the project lifecycle.

How does Point Cloud to BIM improve renovation projects?

It provides accurate as-built documentation, allowing engineers to understand existing conditions and plan practical renovations without disrupting ongoing operations.

What challenges are associated with integrating Point Cloud data into BIM?

Challenges include managing large data sets, ensuring data accuracy, achieving compatibility between software platforms, and requiring specialized skills for practical use.

How does this integration support operational efficiency?

BIM models derived from Point Cloud data enable better maintenance planning and asset management, ensuring pumping stations operate optimally over their lifespan.

What software tools are commonly used for Point Cloud to BIM integration?

Popular tools include Autodesk Revit, Navisworks, and Bentley MicroStation, which support importing and manipulating Point Cloud data within BIM workflows.

What is the potential of Point Cloud for BIM in water infrastructure projects?

As technology advances, the potential for real-time data integration and enhanced automation in monitoring and maintenance will further improve the efficiency and sustainability of water infrastructure projects.

Recent Comments